Accessories

Group Markers

- Group Markers are used for providing common marking for a group of terminal blocks and are mounted using a marking label holder, fixed on end clamp for group marking.

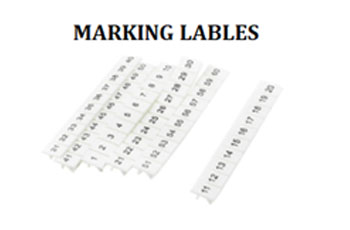

- Marking labels are used for identification of circuit connections. Marking of terminals helps in easy identification and quick maintenance. Marking labels are made of Polyamide in white colour and pre-printed with black indelible ink. They are used to serve different purposes like alpha-numeric identification required for accurate wiring and trouble shooting. Marking labels are available in strips containing 10 markers.

Catalogue Link

Marking Labels

- They are also available in form of a card which consists of 10 such strips. Marking label strip can be snapped on a stack of 10 terminals together. They are available in different sizes with option of either vertically printed numbers or horizontally printed numbers.

Catalogue Link

End clamps

- End clamps also known as End Stoppers are used to hold a stack of terminal blocks on the mounting rail. Depending on the profile of the terminal block stack and the mounting channel, end clamps are available in different sizes and also in different designs. They are either made from Polyamide or Mild Steel duly plated. It is recommended that while selecting the end clamps. due consideration is given to the strength of the support required by the clamps. This is to ensure that the selected end clamps firmly supports the terminal block stack and prevents its movement on the rail and also its dislodging from the rail during normal handling or wiring.

Catalogue Link

End Plates & Barrier Plates

- End plates are used to insulate a stack of terminal blocks. They have same profile as that of the terminal block and are available in different colours to match the colour of the terminal block. For terminal blocks made using Polyamide 6,6 housing, the end plates are "snap-on" type i.e. they get press fitted on the terminal block side whereas in case of Melamine terminal blocks, the end plate require support by end clamps.

- Certain terminal blocks are so designed that they have both the sides closed and hence it is not required to mount on end plate at the end of the stack. However for the other terminal blocks with their one side open, it is normal practice to mount the end plate at the end of the stack to insulate the live parts as a safety measure against an electric shock hazard.

- Barrier plates/ Partition plates are used to serve one or more processes:- To increase clearance and creep age distances in certain applications To provide separation between terminal blocks To readily differentiate stacks of terminal groups

Catalogue Link

Interconnecting links/ Shorting links

- Interconnecting links or shorting links are used to interconnect two or more terminal blocks of same type and at the same potential. it is recommended that factory made shorting links which are designed considering the rated current of the terminal block and its pitch are used for interconnection purpose rather than looping by wire which is not a reliable practice.

-

elmex offers following types of shorting links:-

-

Permanent Cross Connection Link Assembly (CCLA):-

- Removable shorting links are used to interconnect two adjacent terminal blocks temporarily and make switchable cross connection. The links are fitted onto the terminal blocks with long studs and screws. As the links rest above the top surface of the terminal blocks, they can be readily opened up.

- For a pair of terminal blocks to be shorted, one removable link and two studs are required. Further, since the links rest above the top surface of the terminal block, it is recommended to mount a barrier plate/ partition plate between two adjacent pairs of shorted terminal blocks.

-

Removable Shorting Link (RSL):-

- In two types of shorting links as described above, interconnection is made using screws/ studs through a tapped hole in current bar. For certain types of terminal designs, viz. stud type terminal blocks, such interconnection is not possible. As a solution to this problem, shorting links are designed to interconnect adjacent terminal blocks through termination points (where wire is connected) like stud and nut assemblies or clamping units from sides between adjacent terminal blocks. These links are generally available in 2,3,4,5 and 10 ways.

-

Push-in Type Shorting Links (DSL/MSL/SSL):-

- These types of links are designed for screw less type terminal blocks and are available in two ways. A stack of terminal blocks of the same type can be shorted using two-way shorting links. These shorting links are push-in type.

- Current bars in these terminals have provision to accept two shorting links which can be inserted from top. Thus we can short two terminal blocks with one shorting link, three terminals with two shorting links, four terminals with three shorting links and so on.

-

Permanent Cross Connection Link Assembly (CCLA):-