Data Transmission / Communication Cables

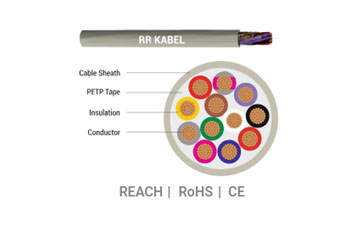

LIYCY (SHEILDED CABLE)

- These cables are used for data and signal transmission application in the electronics of computer systems, electronic control equipment and measuring devices in the tool making and machine industries. The optimum screening substantially reduces the effect of electromagnetic interferences.

-

Cable Construction :

- Bare copper, fine wire conductors stranded according to DIN VDE 0295

- Special PVC core insulation TI2, to EN 50363-3.

- Conductor make-up for

- 0.14 mm² = 18 x 0.1 mm.

- 0.25 mm² = 14 x 0.15 mm.

- 0.34 mm² = 19 x 0.15 mm.

- Colour coded to DIN 47100 (Refer table no. 2-2).

- Cores stranded in layers with optimal lay-length.

- Plastic foil over the laid up cores.

- Tinned copper braided screen, approx 85% coverage.

- Special PVC outer sheath TM2, to EN 50363-4.1.

- Colour grey (RAL 7032).

Catalogue Link

LIYCY (TP)

- The high level of screening reduces substantially the effects of electrical disturbances. These cables are used for data & signal transmission. These cables are integral part of instrumentation in industries for precise signal and data transmission.

-

Cable Construction :

- Bare copper, fine wire conductors stranded according to DIN VDE 0295/ EN 60228 cl. 5,

- Conductor make-up for

- 0.14 mm² = 18 x 0.1 mm.

- 0.25 mm² = 14 x 0.15 mm.

- 0.34 mm² = 19 x 0.15 mm.

- Special PVC core insulation TI2, to EN 50363-3.

- Colour coded to DIN 47100 (Refer table no. 2-1).

- Cores stranded in pair with optimal lay-length.

- Cores stranded in layers with optimal lay-length.

- Tinned copper braided screen, approx. 85% coverage.

- Special PVC outer sheath TM2, to EN 50363-4.1.

- Sheath colour grey (RAL 7032).

Catalogue Link

LI2Y(ST)CY (TP)

- These data cables with twisted pairs are used for interference-free transmission of data and signals over longer distances. The high transmission rate are suitable for RS 422 and RS 485 interfaces. This cable forms an integral part of supervisory control and data acquisition (SCADA) systems. These cables are suitable for fixed installations as well as for flexing applications, for free movement without forced motion and without tensile stress in dry and moist environment.

-

Cable Construction :

- Bare copper stranded 7 wire conductor

- Conductor make-up for

- 0.22 mm² = 7 x 0.20 mm

- 0.34 mm² = 7 x 0.25 mm

- 0.5 mm² = 7 x 0.30 mm

Catalogue Link

LI2Y(ST)CY PIMF

- Absolute disturbance-free data transfer both for installed terminals in all areas of medicine and data technology. Also suitable for use in machine tool and steel producing industries, traffic signal systems, assembly lines and food processing.

-

Cable Construction :

- Bare copper stranded 7 wire conductor.

- Conductor make-up for

- 0.22 mm² = 7 x 0.20 mm

- 0.34 mm² = 7 x 0.25 mm

- 0.5 mm² = 7 x 0.30 mm

- 0.75 mm² = 7 x 0.37 mm

- 1 mm² = 7 x 0.43 mm

Catalogue Link

PROCESS FIELD BUS (ProFiBus)

- Process FIeld BUS is a standard for fieldbus communication in automation technology.

- Process FIeld BUS links controller or control systems with decentralized field devices (sensors and actuators) via a single bus cable on the field level. It also enables consistent data exchange with higher ranking communication systems.

- Consistency of Process Field BUS is enabled by utilizing a single, standardized, application-independent communication protocol (named PROCESS FIeld BUS DP), which, without any difference, supports fieldbus solutions both in factory and process automation as well as in motion control and safety-related tasks.

- To ensure correct interaction between the numerous devices of an automation solution, the basic device functions and services must match in regard to communication, functionality and industry sector solutions.

- This uniformity is achieved by means of “application profiles” which refer to device families or special industry sector requirements, e.g. process automation (PA Devices), Motion Control (PROFIdrive) or integration of HART devices.

- Process Field BUS DP is in the central position and carries communication data between a controller and field devices, preferably in Factory Automation (FA).

- Process Field BUS PA string is connected through a coupler or linking device to enable typical process automation (PA) applications, e.g. in a hazardous environments.

- The controller is connected to Process Field NET as system bus and interface to MES and ERP levels. PA segments can also be connected directly to Process Field NET using proxy technology.

Catalogue Link

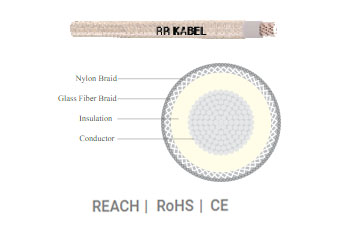

Uninyvin Cable

- These cables are used in UPS systems and server rooms as the nylon and fiber glass braid on the cable does not allows the heat generated in the conductor, due to continuous operation, to be felt in the surrounding areas. These cables are widely used in aircraft cabling.

-

Cable Construction :

- Conductor: Annealed tinned copper to IS:10241 Part 3, uniformly bunched to form a circular shape

- Insulation: Special core insulation HR-PVC 105° C

- Primary Braid: Braided with glass fiber, 100% coverage

- Secondary Braid: Braided with nylon fiber, 100% coverage

- Cores stranded in layers with optimal lay-length.

- Lacquer: Overall construction is finally lacquered with nylon varnish

Catalogue Link

LIYY (Non-sheilded Cable)

- These are special PVC data cables used for flexible use with free movement without tensile stress of forced movements in dry, moist and wet rooms but not suitable for open air, wherever the construction requirements call for a minimum outer diameter.

-

Cable Construction :

- Bare copper, fine wire conductors stranded according to DIN VDE 0295/ EN 60228 cl. 5,

- Special PVC core insulation TI2, to EN 50363-3.

- Conductor make-up for

- 0.14 mm² = 18 x 0.10 mm.

- 0.25 mm² = 14 x 0.15 mm.

- 0.34 mm² = 19 x 0.15 mm.

- Core colours as per DIN 47100 (Refer table no. 2-2).

- Cores stranded in layers with optimal lay-length.

- Plastic foil wrapping for 10 cores and above.

- Special PVC outer sheath TM2, to EN 50363-4.1.

- Colour grey (RAL 7032).

Catalogue Link

LIYY TP (Non-sheilded Cable)

- LiYY (TP) is applicable in the short runs and tight spaces, where the main requirements are smaller outer diameter and bending radii. The cable ideally meets these requirements.

-

Cable Construction :

- Bare copper, fine wire conductors stranded according to DIN VDE 0295

- Conductor make-up for

- 0.14 mm² = 18 x 0.10 mm.

- 0.25 mm² = 14 x 0.15 mm.

- 0.34 mm² = 19 x 0.15 mm.

- Core insulation of special PVC TI2 EN 50363-3.

- Core colours as per DIN 47100 (Refer table no. 2-1).

- Pairs stranded in layers with optimal lay-length.

- Plastic foil wrapping over laid up pairs.

- Outer sheath of special PVC, TM2 to EN 50363-4.1.

- Colour grey (RAL 7032).